3.5 oz. Sweet Almond Oil

8.75 oz. Coconut Oil

1.75 oz. Meadowfoam Oil

8.75 oz. Olive Oil

10.5 oz. Palm Oil

1.75 oz. Shea Butter

4.9 oz. Sodium Hydroxide

11.6 oz. Distilled water

2 oz. Lavender and Cedar Fragrance Oil

Kaolin Clay

Sea Clay

Hydrated Chrome Green Pigment

Pink Sea Salt, Medium

Tall 12″ Silicone Loaf Mold

If you’ve never made Cold Process soap before, check out our FREE four part SoapQueen.tv series on Cold Process Soapmaking, especially the episode on lye safety. Bramble Berry also carries a wide range of books on the topic, including Soap Crafting. You can also checkout the digital downloads.

SAFETY FIRST: Suit up for safety! That includes goggles, gloves and long sleeves. Make sure kids, pets, and other distractions and tripping hazards are out of the house or don’t have access to your soaping space. Always soap in a well-ventilated area.

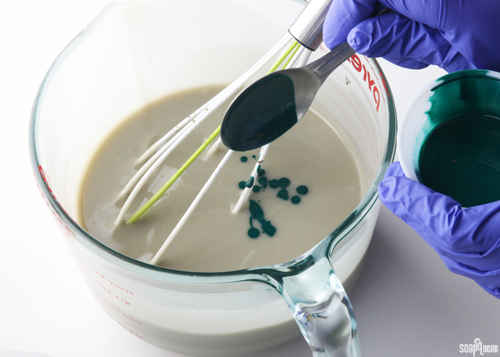

COLOR PREP: Add 1 teaspoon of Hydrated Chrome Green Pigment into 1 tablespoon of sweet almond oil (or any other lightweight liquid oil). Mix 2 teaspoons of the kaolin clay into 2 tablespoons of distilled water. Then, disperse 2 teaspoons of sea clay into 2 tablespoons of distilled water. To get the clumps worked out, use a mini mixer.

ONE: Carefully and slowly add the lye to the water and stir until the lye is fully dissolved and the liquid is completely clear. Set the lye and water aside to cool.

TWO: Melt and combine the palm, olive, coconut, shea, sweet almond and meadowfoam oils. Remember to fully melt and mix your entire container of palm oil before adding it to the mixture. Once the oils and lye water have cooled to 120 degrees or below (and ideally within 10 degrees of each other), add the lye water to the oils. Stick blend until you reach thin trace. If you want a harder bar of soap that releases faster from the mold, add sodium lactate to your cooled lye water. Add 1 teaspoon of sodium lactate per pound of oils in the recipe. For this recipe, you would add about 2 teaspoons of Sodium Lactate to your lye water.

THREE: Once the soap is at a light trace, split the batch in half. Each container of soap should have about 3.5 cups. To one of the containers, add 1/2 tbs. of the dispersed Hydrated Chrome Green and all of the dispersed sea clay. Use a whisk to mix the colorants in fully.

THREE: Once the soap is at a light trace, split the batch in half. Each container of soap should have about 3.5 cups. To one of the containers, add 1/2 tbs. of the dispersed Hydrated Chrome Green and all of the dispersed sea clay. Use a whisk to mix the colorants in fully.

FOUR: To the second container, add all of the dispersed kaolin clay. Whisk the clay in to fully incorporate.

FOUR: To the second container, add all of the dispersed kaolin clay. Whisk the clay in to fully incorporate.

FIVE: Add about half of the Lavender and Cedar Fragrance Oil into each container of soap and whisk it in.

FIVE: Add about half of the Lavender and Cedar Fragrance Oil into each container of soap and whisk it in.

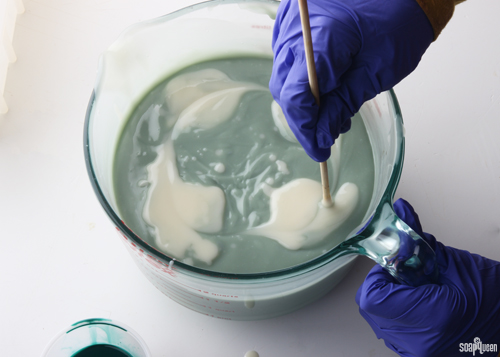

SIX: For the in-the-pot swirl design, pour the white soap into the green soap in 4 places: 12:00 o’clock, 3:00 o’clock, 6:00 o’clock and 9:00 o’clock. Pour the soap from a high point so it penetrates the entire depth of the container. That will create a swirl in your soap.

SIX: For the in-the-pot swirl design, pour the white soap into the green soap in 4 places: 12:00 o’clock, 3:00 o’clock, 6:00 o’clock and 9:00 o’clock. Pour the soap from a high point so it penetrates the entire depth of the container. That will create a swirl in your soap.

SEVEN: Run a chopstick or dowel through each of the entry points once. Only do this once – you want to swirl the soap, not mix it.

SEVEN: Run a chopstick or dowel through each of the entry points once. Only do this once – you want to swirl the soap, not mix it.

EIGHT: Pour your soap into the mold. Keep the container in one place while you’re pouring. Tap the mold on the tabletop to pop any air bubbles.

EIGHT: Pour your soap into the mold. Keep the container in one place while you’re pouring. Tap the mold on the tabletop to pop any air bubbles.

NINE: Use a spoon to create texture and peaks on top. When you have the texture you like, sprinkle the top of the soap with pink sea salt. Spray your soap with 99% isopropyl alcohol to help prevent soda ash.

NINE: Use a spoon to create texture and peaks on top. When you have the texture you like, sprinkle the top of the soap with pink sea salt. Spray your soap with 99% isopropyl alcohol to help prevent soda ash.

TEN: After 3-4 days, unmold the soap and allow it to cure for 4-6 weeks. When you cut the soap, turn it on its side to avoid pulling salt through your soap. That helps prevent drag marks. Enjoy!

TEN: After 3-4 days, unmold the soap and allow it to cure for 4-6 weeks. When you cut the soap, turn it on its side to avoid pulling salt through your soap. That helps prevent drag marks. Enjoy!