What You’ll Need:

5 Pound Mold with Sliding Bottom

Silicone Liner for 5 lb Wood Mold

Hanger Swirl Tool

54 oz. Swirl Quick Mix

7.5 oz. Sodium Hydroxide Lye

17.8 oz. Distilled Water

Magenta Mica

Sunset Orange Mica

Merlot Sparkle Mica

Black Oxide

Titanium Dioxide

2 oz. Apple Sage Fragrance Oil

1.5 oz. Yacht Club Fragrance Oil

If you’ve never made Cold Process soap before, stop here! I highly recommend checking out our FREE four part SoapQueen.tv series on Cold Process Soapmaking, especially the episode on lye safety. And if you’d rather do some reading, Bramble Berry carries a wide range of books on the topic, including my newest book, Pure Soapmaking. You can also check out the digital downloads for that instant gratification factor.

SAFETY FIRST: Suit up for safe handling practices! That means goggles, gloves and long sleeves. Make sure kids, pets, and other distractions and tripping hazards are out of the house or don’t have access to your soaping space. Always soap in a well-ventilated area.

COLOR PREP: To ensure that the Titanium Dioxide blends smoothly into the soap batter, we recommend micronizing it before dispersing it in oil. Please note this is an optional tip but it does help with the titanium dioxide clumping in the soap. =) To micronize colorant, simply use a coffee grinder to blend the colorant to break up any clumps of color and prevent streaks of white from showing in the final soap. We like to use a coffee grinder that has a removable, stainless steel mixing area for easy cleaning. Then, disperse 3 teaspoons of the colorant into 3 tablespoons of sunflower or sweet almond oil (or any other liquid oil). Then in separate containers disperse 1/2 teaspoon Magenta Mica, Sunset Mica, and Merlot Sparkle Mica into 1/2 tablespoon of oil. Finally, disperse 1/2 tsp. Black Oxide with 1/2 tablespoon lightweight liquid oil. Use a mini mixer to get rid of any clumps.

FRAGRANCE OIL PREP: Measure 2 oz. Apple Sage Fragrance Oil and 1.5 oz. Yacht Club Fragrance Oil in a glass, fragrance oil safe container. Set aside.

MOLD & TOOL PREP: Insert the silicone liner into the wood mold. Bend the hanger tool so it fits inside the mold by length with silicone liner.

ONE: Slowly and carefully add the lye to the water and gently stir until the lye has fully dissolved and the liquid is clear. Set aside to cool.

TWO: Fully melt the Swirl Recipe Quick Mix oils until completely clear. Once the lye water and the oils have cooled to 110-120 F degrees or below (and are ideally within 10 degrees of each other), add the lye water to the oils and stick blend until thin trace. If you’d like a harder bar of soap that releases faster from the mold, you can add sodium lactate to the cooled lye water. Use 1 teaspoon of sodium lactate per pound of oils in the recipe. For this recipe, you’d add about 3.5 teaspoons sodium lactate.

THREE: Once you reach a thin trace, split the batter into three equal containers. Each container will be about 800 mL.

THREE: Once you reach a thin trace, split the batter into three equal containers. Each container will be about 800 mL.

FOUR: To one container, add all of the dispersed titanium dioxide and use a whisk to fully mix in the colorant.

FOUR: To one container, add all of the dispersed titanium dioxide and use a whisk to fully mix in the colorant.

FIVE: To another container, add 1 tsp. dispersed Magenta Mica, 1/4 tsp. dispersed Merlot Sparkle Mica and 3/4 tsp. dispersed Sunset Orange Mica. Use a whisk to fully mix in the colorants. To the last container, add 1 tsp. dispersed black oxide and whisk in.

FIVE: To another container, add 1 tsp. dispersed Magenta Mica, 1/4 tsp. dispersed Merlot Sparkle Mica and 3/4 tsp. dispersed Sunset Orange Mica. Use a whisk to fully mix in the colorants. To the last container, add 1 tsp. dispersed black oxide and whisk in.

SIX: Add 1/3rd of the fragrance oil blend (it’s okay to eyeball it!) to the black soap and use a whisk to fully mix in.

SIX: Add 1/3rd of the fragrance oil blend (it’s okay to eyeball it!) to the black soap and use a whisk to fully mix in.

SEVEN: Add half of the black soap into the mold. Tap the mold firmly on the counter to help get rid of bubbles and evenly disperse the soap.

SEVEN: Add half of the black soap into the mold. Tap the mold firmly on the counter to help get rid of bubbles and evenly disperse the soap.

EIGHT: Add 1/3rd of the fragrance oil blend into the white soap, and use a whisk to completely stir in. Then, very carefully, spoon half of the white soap on top of the black. Be careful not to let the white soap break through to the black layer below. Tap the mold on the counter to help evenly disperse the white soap throughout the mold.

EIGHT: Add 1/3rd of the fragrance oil blend into the white soap, and use a whisk to completely stir in. Then, very carefully, spoon half of the white soap on top of the black. Be careful not to let the white soap break through to the black layer below. Tap the mold on the counter to help evenly disperse the white soap throughout the mold.

NINE: Add 1/3rd of the fragrance oil blend into the red soap, and use a whisk to stir in. Very carefully, spoon half of the red soap on top of the white. Be careful to not break through to the white layer below. Tap the mold firmly on the counter to help get rid of any bubbles and disperse the soap throughout the mold.

NINE: Add 1/3rd of the fragrance oil blend into the red soap, and use a whisk to stir in. Very carefully, spoon half of the red soap on top of the white. Be careful to not break through to the white layer below. Tap the mold firmly on the counter to help get rid of any bubbles and disperse the soap throughout the mold.

TEN: Stir all three colors of soap with a whisk to help them stay fluid and pourable. Gently add the remaining black soap on top of the red, leaving behind a very small amount of the black soap to create the swirl on top. Tap the mold on the counter to help disperse the soap. Add the remaining white soap on top of the black, leaving behind a small amount for the swirl on top.

TEN: Stir all three colors of soap with a whisk to help them stay fluid and pourable. Gently add the remaining black soap on top of the red, leaving behind a very small amount of the black soap to create the swirl on top. Tap the mold on the counter to help disperse the soap. Add the remaining white soap on top of the black, leaving behind a small amount for the swirl on top.

ELEVEN: Spoon the remaining red soap on top of the white. Use a small spoon to even out the top. Tap firmly on the counter to get rid of bubbles.

ELEVEN: Spoon the remaining red soap on top of the white. Use a small spoon to even out the top. Tap firmly on the counter to get rid of bubbles.

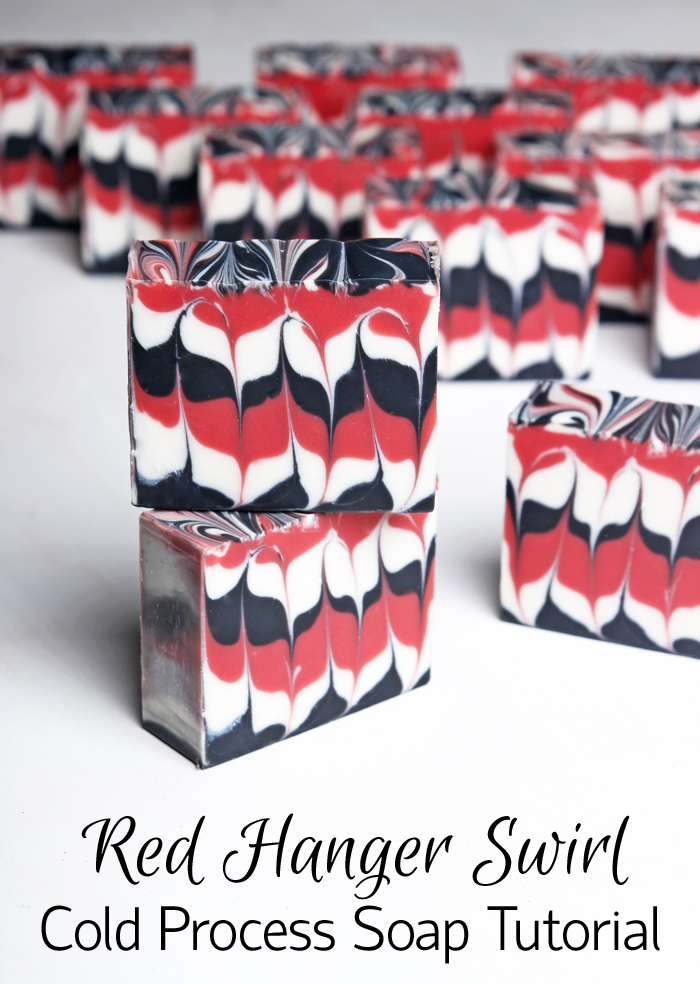

TWELVE: Now it’s time to make the hanger swirl! Insert the hanger into the soap against the long side of the mold furthest away from you. Drag the hanger against the bottom of the mold toward you. Once you drag the hanger about 1/6th of the way, pull the hanger up until it almost breaks through the top of the soap, but not quite. Move the hanger towards you about 1/6th of the way. Push the hanger back down into the soap, and drag the hanger against the bottom of the mold and move it towards you again, moving about 1/6th of the way. Bring the hanger up until it almost breaks the top, then move it over and push it back down.

TWELVE: Now it’s time to make the hanger swirl! Insert the hanger into the soap against the long side of the mold furthest away from you. Drag the hanger against the bottom of the mold toward you. Once you drag the hanger about 1/6th of the way, pull the hanger up until it almost breaks through the top of the soap, but not quite. Move the hanger towards you about 1/6th of the way. Push the hanger back down into the soap, and drag the hanger against the bottom of the mold and move it towards you again, moving about 1/6th of the way. Bring the hanger up until it almost breaks the top, then move it over and push it back down.

THIRTEEN: Continue the “down, over, up, over, down, over, up, over” process until you reach the other side of the mold. Once done, tap the mold firmly on the counter and smooth out the top of the soap with a spoon.

THIRTEEN: Continue the “down, over, up, over, down, over, up, over” process until you reach the other side of the mold. Once done, tap the mold firmly on the counter and smooth out the top of the soap with a spoon.

FOURTEEN: Drizzle the remaining white and black soap on top of the red soap in thin lines. No need to be super precise, you can see mine looked quite “abstract.” =)

FOURTEEN: Drizzle the remaining white and black soap on top of the red soap in thin lines. No need to be super precise, you can see mine looked quite “abstract.” =)

FIFTEEN: Insert a dowel or chopstick into the very top of the soap. You don’t want to disrupt your layers below! Starting in a corner, drag the dowel or chopstick in large “S” curves width wise down the length of the mold.

FIFTEEN: Insert a dowel or chopstick into the very top of the soap. You don’t want to disrupt your layers below! Starting in a corner, drag the dowel or chopstick in large “S” curves width wise down the length of the mold.

SIXTEEN: Clean off the dowel, then insert it again into the very top of the soap and drag it up and down the length of the mold in an “S” curve. Spritz with 99% isopropyl alcohol to prevent soda ash and cover the soap to insulate for 24 hours.

Allow the soap to stay in the mold for 2-3 days. Remove from the mold and cut into bars. Allow the soap to cure for 4-6 weeks. Enjoy!