What You’ll Need:

10″ Silicone Loaf Mold

3.3 oz. Sweet Almond Oil (10%)

3.3 oz. Canola Oil (10%)

1 oz. Castor Oil (3%)

6.6 oz. Coconut Oil (20%)

12.2 Olive Oil (37%)

6.6 oz. Palm Oil (20%)

4.5 oz. Sodium Hydroxide Lye

10.9 oz. Distilled Water

1.4 oz. Green Fig Fragrance Oil

1 oz. Pomegranate & Black Currant Fragrance Oil

Black Oxide

Titanium Dioxide

Ultramarine Blue Oxide

Green Chrome Oxide

Ultramarine Violet Oxide

If you’ve never made Cold Process soap before, stop here! I highly recommend checking out our FREE four part SoapQueen.tv series on Cold Process Soapmaking, especially the episode on lye safety. And if you’d rather do some reading, Bramble Berry carries a wide range of books on the topic, including my newest book, Soap Crafting. You can also checkout the digital downloads for that instant gratification factor.

If you’ve never made Cold Process soap before, stop here! I highly recommend checking out our FREE four part SoapQueen.tv series on Cold Process Soapmaking, especially the episode on lye safety. And if you’d rather do some reading, Bramble Berry carries a wide range of books on the topic, including my newest book, Soap Crafting. You can also checkout the digital downloads for that instant gratification factor.

SAFETY FIRST: Suit up for safe handling practices! That means goggles, gloves and long sleeves. Make sure kids, pets, and other distractions and tripping hazards are out of the house or don’t have access to your soaping space. Always soap in a well-ventilated area.

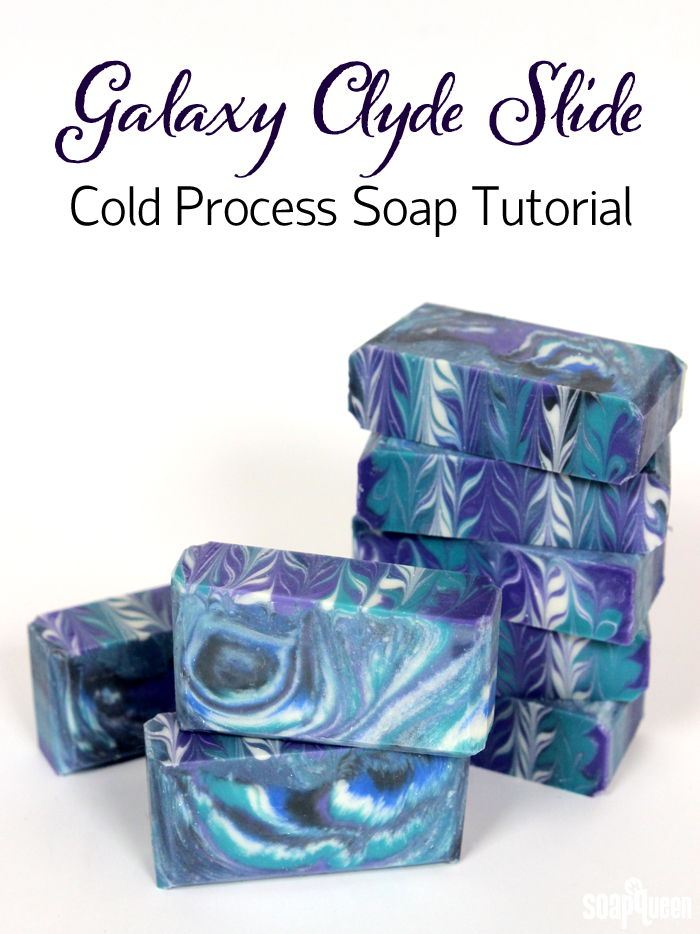

COLOR PREP: To ensure that the Titanium Dioxide blends smoothly into the soap batter, we recommend micronizing it before dispersing it in oil. Please note this is an optional tip but it does help with the titanium dioxide clumping in the soap. =) To micronize colorant, simply use a coffee grinder to blend the colorant to break up any clumps of color and prevent streaks of white from showing in the final soap. We like to use a coffee grinder that has a removable, stainless steel mixing area for easy cleaning. Then, disperse 1 teaspoons of the colorant into 1 tablespoon of sunflower or sweet almond oil (or any other liquid oil). Then in separate containers, disperse 1 teaspoon of the Green Chrome Oxide, Black Oxide, Ultramarine Violet Oxide and Ultramarine Blue Oxide into 1 tablespoon of lightweight liquid oil. Use a mini mixer to get rid of any clumps.

FRAGRANCE PREP: Blend together 1.4 ounces of Green Fig Fragrance Oil and 1 ounce of Pomegranate and Black Currant Fragrance Oil in a glass, fragrance oil safe container. Set aside.

ONE: Slowly and carefully add the lye to the water and gently stir until the lye has fully dissolved and the liquid is clear. Set aside to cool.

TWO: Melt and combine the coconut oil, olive oil, canola oil, castor oil, sweet almond oil and palm oils (remember to fully melt then mix your entire container of palm oil before portioning). Once the lye water and the oils have cooled to 130 degrees or below (and are ideally within 10 degrees of each other), add the lye water to the oils and stick blend until thin trace. If you’d like a harder bar of soap that releases faster from the mold, you can add sodium lactate to the cooled lye water. Use 1 teaspoon of sodium lactate per pound of oils in the recipe. For this recipe, you’d add about 2 teaspoons of sodium lactate.

THREE: Once the batter has reached a very light trace, pour the batter into five equal containers. Each container will hold about 250 mL.

THREE: Once the batter has reached a very light trace, pour the batter into five equal containers. Each container will hold about 250 mL.

FOUR: To each container, add the following amounts of dispersed colorants below and use a spoon or whisk to fully mix in.

FOUR: To each container, add the following amounts of dispersed colorants below and use a spoon or whisk to fully mix in.

- A: 2 teaspoons dispersed Titanium Dioxide

- B: 1/4 teaspoon dispersed Black Oxide

- C: 1/2 teaspoon dispersed Ultramarine Blue Oxide

- D: 1 1/4 teaspoon dispersed Ultramarine Violet Oxide + 1/8 teaspoon Ultramarine Blue Oxide

- E: 1/4 teaspoon dispersed Ultramarine Blue Oxide + 1/2 teaspoon dispersed Green Chrome Oxide + 1/4 teaspoon dispersed Titanium Dioxide

FIVE: Add the fragrance blend evenly into each container. It’s okay to eyeball it! If your soap still has an extremely thin trace, pulse each container with the stick blender (from lightest to darkest) for about 3-5 seconds to slightly thicken the mixture. You want the consistency to be thin enough to easily pour, but thick enough that the colors won’t mix together.

FIVE: Add the fragrance blend evenly into each container. It’s okay to eyeball it! If your soap still has an extremely thin trace, pulse each container with the stick blender (from lightest to darkest) for about 3-5 seconds to slightly thicken the mixture. You want the consistency to be thin enough to easily pour, but thick enough that the colors won’t mix together.

SIX: Choose the color order that you would like to use. The order I used was black, purple, teal, white, blue. But you can use whatever order you like. You just want to keep the order consistent. Begin pouring the first color into a large bowl, allowing the soap to run down the side of the bowl slightly. As you pour count “1, 2, 3, 4” to keep each pour consistent. The amount of soap you pour at a time is up to you; the more soap you pour into the bowl at a time, the less total layers there will be.

SIX: Choose the color order that you would like to use. The order I used was black, purple, teal, white, blue. But you can use whatever order you like. You just want to keep the order consistent. Begin pouring the first color into a large bowl, allowing the soap to run down the side of the bowl slightly. As you pour count “1, 2, 3, 4” to keep each pour consistent. The amount of soap you pour at a time is up to you; the more soap you pour into the bowl at a time, the less total layers there will be.

Continue pouring each color into the bowl, counting during each pour until each color is almost used up. Save a small amount of the white, purple and teal shades (or whichever colors you prefer) to do a swirl design on the top.

SEVEN: Once the soap has been poured into the mixing bowl, carefully pour the soap into one corner of the mold until completely filled. The colors will begin to blend together, but that’s okay. Once completely filled, tap the mold on the counter firmly to help get rid of any bubbles.

SEVEN: Once the soap has been poured into the mixing bowl, carefully pour the soap into one corner of the mold until completely filled. The colors will begin to blend together, but that’s okay. Once completely filled, tap the mold on the counter firmly to help get rid of any bubbles.

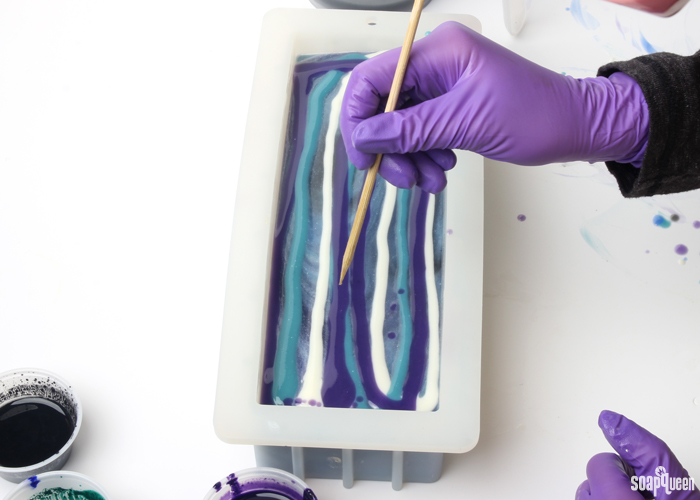

EIGHT: Using the leftover soap, carefully pour thin lines of each color lengthwise down the mold on the top of the soap. Pour carefully to ensure the colors do not break through into the soap.

EIGHT: Using the leftover soap, carefully pour thin lines of each color lengthwise down the mold on the top of the soap. Pour carefully to ensure the colors do not break through into the soap.

NINE: Once each color has been placed on top, drag a dowel or chopstick vertically in an S-shaped curve across the lines of soap you just poured. Continue this pattern down the entire length of the mold. Do not insert the chopstick into the bottom of the mold, you only want to swirl the very top.

NINE: Once each color has been placed on top, drag a dowel or chopstick vertically in an S-shaped curve across the lines of soap you just poured. Continue this pattern down the entire length of the mold. Do not insert the chopstick into the bottom of the mold, you only want to swirl the very top.

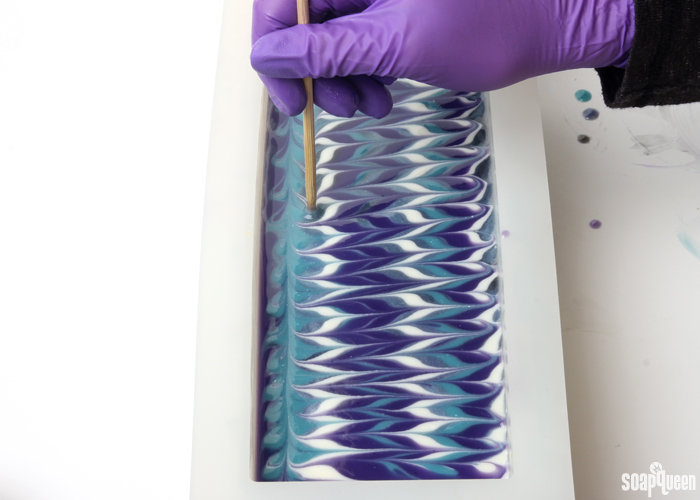

TEN: Then, use the dowel or chopstick to create S-shaped curves down the length of the mold in the opposite direction. Spritz with 99% isopropyl alcohol to prevent soda ash. Cover the soap and insulate for 24 hours. Allow the soap to stay in the mold for 3-4 days. Unmold, and cut into bars. Allow the bars to cure for 4-6 weeks. Enjoy!

TEN: Then, use the dowel or chopstick to create S-shaped curves down the length of the mold in the opposite direction. Spritz with 99% isopropyl alcohol to prevent soda ash. Cover the soap and insulate for 24 hours. Allow the soap to stay in the mold for 3-4 days. Unmold, and cut into bars. Allow the bars to cure for 4-6 weeks. Enjoy!